What is ferrofluid feedthrough seal?

2020-08-19

As the industry leader in Ferrofluid seals and vacuum rotary feedthroughs, Our products are widely recognized for quality and performance of the ferrofluid that we use in our seals. With over thirty years of experience producing seals for the world’s most demanding applications, we have been able to optimize our ferrofluid products for the most intense performance requirements.

Because we produce our own ferrofluid, our products can be optimized to the unique demands of target applications. This enables our solutions to outperform competitive products in the most demanding, high-precision applications.

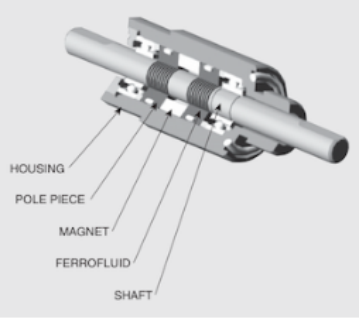

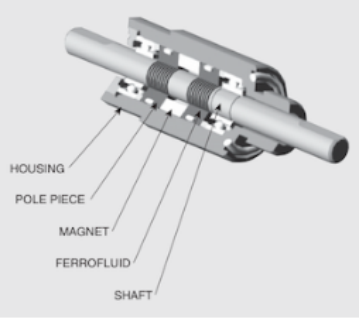

A Ferrofluid seal takes advantage of the response of a magnetic fluid to an applied magnetic field. The basic seal components include ferrofluid, a permanent magnet, two pole pieces and a magnetically permeable shaft. The magnetic circuit, completed by the stationary pole pieces and the rotating shaft, concentrates magnetic flux in the radial gap under each pole piece. When fluid is applied to this gap it assumes the shape of a liquid O-ring and produces a hermetic seal.

The vacuum rotary feedthroughs utilize multiple rings of ferrofluid contained in stages formed by grooves machined into either the shaft or pole pieces. Typically a single stage can sustain a pressure differential of 0.2 atmospheres (200 mbar). The pressure capacity of the entire feedthrough is approximately equal to the sum of the pressure capacities of the individual stages.

The typical products we building

Shaft Type:

l Solid shaft

l Hollow shaft

Mount Type :

l Cartridge mount

l Flange mount

l Nose mount

l Nut mount

(Chat Online)

(Chat Online)