Lubricating with oil is only advisable with applications in which the oil temperature does not exceed 70℃。

Hunan Jintai Hardware and Machinery Co.,Ltd. is a professional manufacturer on various kind of bearings over 15 years China factory.

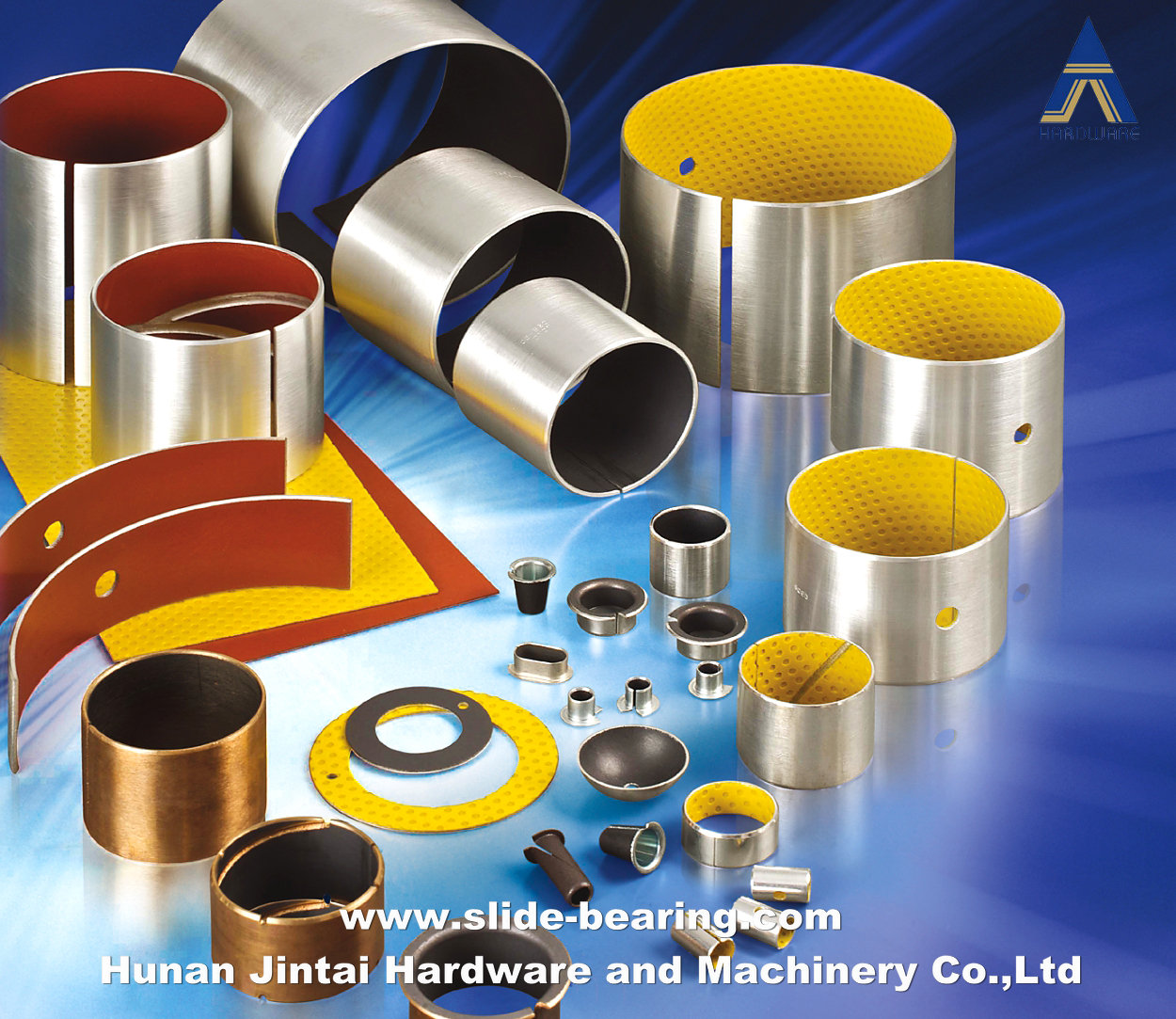

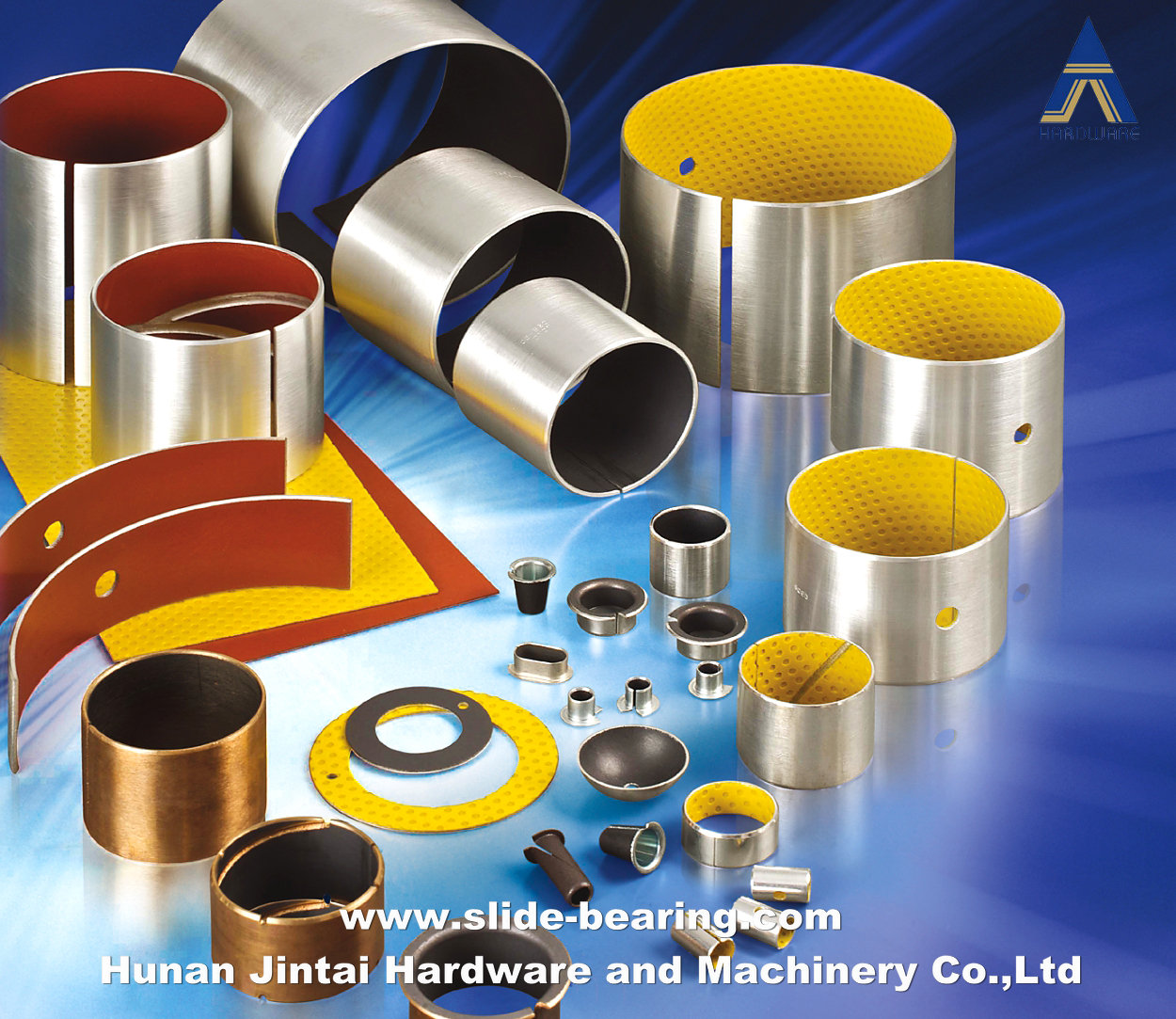

We are making all kinds of slide bearings including wrapped bronze bushing,JF bimetal bearing,DU PTFE composit bushing,DX POM composite bushing,cast sliding bushings and wear plate bearing pad, sintered bronze bushing and sintering parts, ball transfer bearings, etc.

The shapes of bearings can be in sleeve, flanged, spherical, plate, washer, pad, ring, square etc.

Base materials in carbon steel, harden steel, iron, stainless steel, bronze, brass, copper, bronze-steel alloy.Lubricant materials in PTFE, teflon, POM, nylon, plastic, oil, graphite, grease, MoS2, etc.

Export to Germany,Italy,Spain,Sweden,,Estonia,Ukraine,Turkey,Malaysia, Brunei, Singapore, Indonesia, East Timor,Nepal, Bhutan, Bangladesh, India, Pakistan, America,Canada,Brazil,Peru,Argentina,Chile,Paraguay,Europe,Poland,Sweden, Norway, Iceland, Denmark, Faroe Islands, Czech Republic, Slovakia, Hungary, Austria,Switzerland,Liechtenstein,Britain,Finland,France,Austrial,Russia,Korea,Malaysia,Singapore,Belize, El Salvador, Honduras, Nicaragua, Costa Rica, Panama,Bahamas, Cuba, Jamaica, Haiti, Dominica, Antigua and Barbuda, Saint Kitts and Nevis, Dominica, Saint Lucia, Saint Vincent and the Grenadines, Grenada, Barbados, Trinidad and more Bagh, Puerto Rico, Anguilla,Thailand,Egypt,Kenya,Somali,Congo,Zimbabwe,South Africa,etc.

(Chat Online)

(Chat Online)