How to Install a Slide Bearing Bushing

2015-10-27

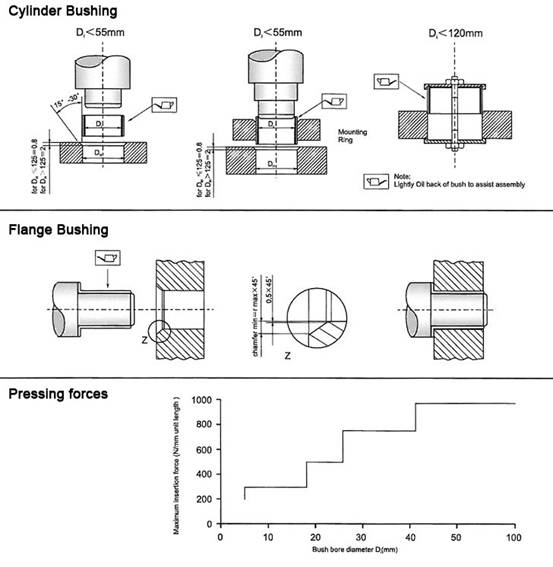

Before installation, you need prepare the install tools, normally it is done by a hydraulic press machine with a solid flange steel arbor in little smaller than bushing bore size.Also you can design the arbor combined with different sizes step.Below picture will show the arbor tools and install ways for cylinder bushings and flange bushings:

If the installation of the bushing is not done properly or the quality-testing methods fall short, a variety of problems can arise.There are three important factors for proper bushing installation.By following the installation tips outlined below and ensuring the proper quality checks have been performed, your bearings should work well from the point of installation.

First, you should use an arbor press to press-fit the bushings. This is the most efficient installation method and will preserve the integrity of the bushing. For example, if you use a hammer, the installation of the bushing might be uneven.

Next, ensure the housing has a chamfer, recommends 25-30 degrees,and that it is press-fit with the outside chamfer of the bushing against the housing chamfer (All of our bushings have chamfer on both sides and ends ).

Finally, ensure your ID-after-press-fit matches your supplier's recommended tolerances for the bushing. All measurement testing should be conducted after the bushing is press-fit into the housing.

(Chat Online)

(Chat Online)