Bearing product specific industry needs and installation environment

2018-04-25

Hunan Jintai Hardware and Machinery Co., Ltd. describes the specific industry needs and installation environment of bearing products.

It is understood that motor vehicles and machinery shopping malls account for more than 70% of the global demand for sliding bearings. Although the two malls still account for the largest proportion of shopping malls in 2016, the sales of sliding bearings for aerospace and other applications will accelerate, which will reduce the overall sales of motor vehicles and mechanical plain bearing suppliers. All sales in these malls will be driven by the greater output of aircraft, railway equipment, motorcycles, electronic equipment, and medical equipment in developing countries, as well as moderate returns from similar products from other parts of the world.

Oilless bearing devices need to be carried out under boring, clean environmental conditions. Before the installation, the cooperative appearance of the shaft and the housing, the end face of the shoulder, the groove and the appearance of the engagement surface should be carefully checked. It is necessary to carefully clean and remove the burrs in all the cohesive appearances. It is necessary to remove the net sand from the unfinished surface of the castings.

Oil-free bearing devices should be cleaned with gasoline or kerosene before use, and should be used after boring, and to ensure outstanding smooth, oil-free bearings generally use smooth grease, but also can choose smooth oil. When smooth grease is used, smooth grease with no impurities, oxidation resistance, rust resistance, and extreme pressure properties should be used. The grease filling amount is 30%-60% of the volume of oil-free bearings and non-oil bearing boxes, and should not be too much. Double-row tapered roller oil-free bearings with sealed construction and water pump shafts with oil-free bearings have been filled with a smooth grease that can be used by the user without cleaning.

Hunan Jintai Hardware and Machinery Co.,Ltd. is a professional manufacturer on various kind of bearings over 15 years China factory.

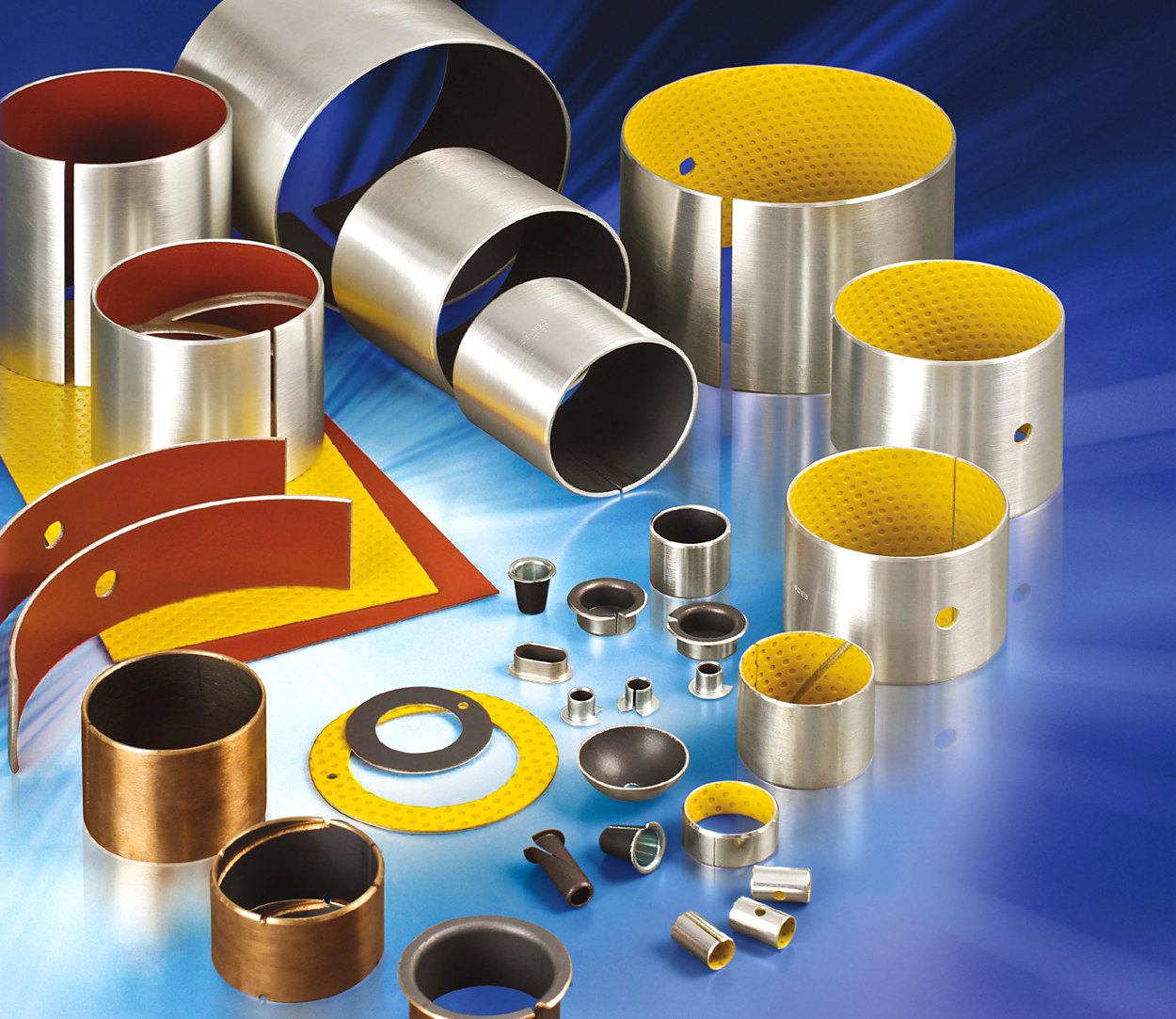

We are making all kinds of slide bearings including DU PTFE composit bushing, DX POM composite bushing,bimetal bushing,wrapped bronze bushing, cast sliding bushings and wear plate bearing pad, sintered bronze bushing and sintering parts, ball transfer bearings, etc.

The shapes of bearings can be in sleeve, flanged, spherical, plate, washer, pad, ring, square etc.

Base materials in carbon steel, harden steel, iron, stainless steel, bronze, brass, copper, bronze-steel alloy.Lubricant materials in PTFE, teflon, POM, nylon, plastic, oil, graphite, grease, MoS2, etc.

Export to America,Canada,Brazil,Peru,Argentina,Chile,Paraguay,Europe,Finland,France,Germany,Italy,Spain,Sweden,

Britain,Estonia,Ukraine,Turkey,Austrial,Russia,Korea,Malaysia,Singapore,Thailand,Egypt,Kenya,Somali,

Congo,Zimbabwe,South Africa,etc.

(Chat Online)

(Chat Online)